Blasting media Difference of Glass beads, Ceramic beads and steel

shot in sandblasting

DESCRIPTION

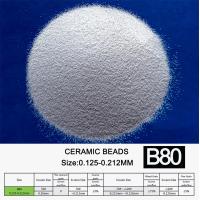

Ceramic blasting media is also called Ceramic beads, ZrO2 60-66%,

Bulk Density 2.3g/cm3,

Ceramic beads is of high impact properties coupled with good

hardness, and is an ideal sandblasting media.

Ceramic sand is of wide range of sizes from B20-B505.

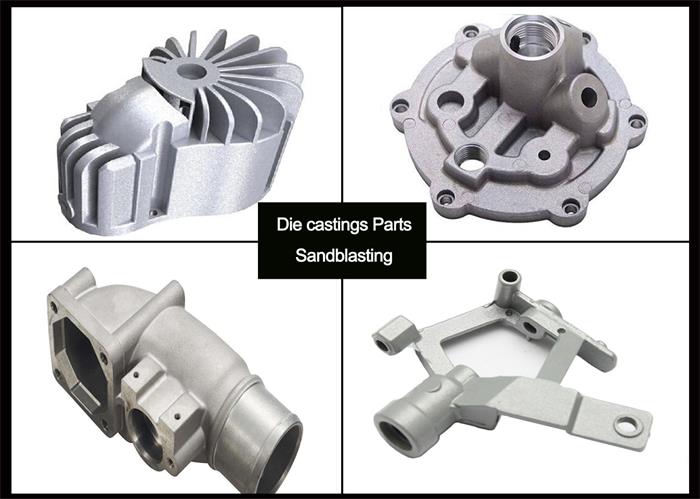

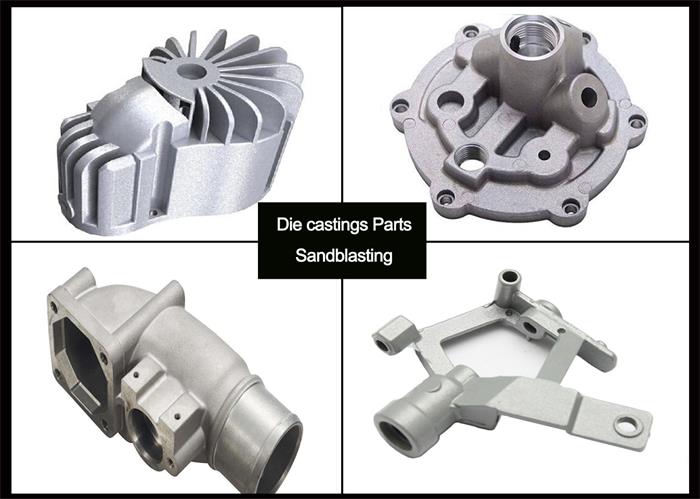

It is mainly used for surface treatment of aluminum alloy zinc

alloy magnesium alloy die castings, etc.

SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 | Special sizes can be customized |

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 |

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

FEATURES

1. The density of the ceramicbeads is between glass beads and steel shot, and

with high hardness, can be used to fill the upper and lower limit

of the strength of glass beads and steel shot.

2. The ceramic beads is light, but its hardness is high, which is very suitable for the strengthening and forming of metal

blasting sand such as titanium alloy, aluminum alloy and high

temperature alloy.

3. Ceramic beads is not deformed in the process of circulation and wear low, which can ensure the consistency of the surface sandblasting effect during mass production.

4. Ceramic beads is spherical and has smooth surface and low loss of equipment.

5. Ceramic beads has a wider range of particle size and can be used

in matching with various types of sandblasting machines to meet more application requirements.

APPLICATION

Sandblasting for die-casting parts cleaning and pre-treatment.

Sandblasting is a relatively thorough and efficient cleaning method

and can be arbitrarily selected between different roughness.

APPLICABLE EQUIPMENT

Dry sandblasting machine and Wet sandblasting machine

CONTACT US

No matter you’re the end users, blasting service suppliers,

sandblasting equipment dealers or ceramic blasting media and other

blasting abrasive distributors, welcome to contact us. More details

of ceramic blasting beads, updated prices and samples will be

available.

Caroline Cui

Zhengzhou Zhengtong Abrasive Imp.&Exp. Co., Ltd

Address: Ximazhuang, Liuzhai Town, Xinmi City, Henan, China

Tel.:+371 86592608

Mob.: +86 15003865330

Email: caroline@zzztabrasive.com