Ceramic Blasting Media B170 45-90μm B205 0-63μm B400 30-63μm for

Orthopedic Implants

1. Product Description of Ceramic Blasting Media

Ceramic Beads selects the high quality zircon sand as main raw

material,then fused in arc furnace under

high temperature over 2000 degrees,then made into different

microbeads through special technology.

Ceramic beads has medium density and high hardness,which can

provide high impact speed in blasting

process,so it is one ideal choice for surface sandblasting and shot

peening,especially suitable for titanium

parts.

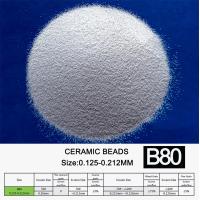

2. Main Technical Data of Ceramic Beads

| Commodity Name | Chemical Index | Physical Index |

| Ceramic Blasting Beads | ZrO2 60-66% SiO2 25-30%

Al2O3 7-13% | Vickers Hardness ≥700 HV |

| True Specific Gravity ≥3.85 g/cm3 |

| Bulk Density≥2.3g/cm3 |

| Particle Size | B20: 0.600-0.850mm |

| B30:0.425-0.600mm |

| B40:0.250-0.425mm |

| B60:0.150-0.300mm |

| B80:0.125-0.212mm |

| B100:0.106-0.180mm |

| B120:0.063-0.125mm |

| B150:0.000-0.125mm |

| B170:0.045-0.090mm |

| B205: 0.000-0.063mm |

| B400: 0.030-0.063mm |

| B505: 0.010-0.030mm |

| Special specification can be customized |

3. Main Applications of Ceramic Blasting Media

Surface finish for hardware industries: hardware

parts,springs,motor casing,door handles,lock cylinder etc.

Surface cleaning for molds industries: glass-bottle molds,tire

molds,rubber molds etc

Surface finishing for mechnical parts,Cylinder head,artifical limb

& joints,gears,glasses frames etc

Deburring for electronic & plastics industries: electronic circult

board,plastic parts...

Surface strengthening treatment for automotive industries: gear-box

built-in parts,Turbine....

Surface finishing for golf head,golf club...

4. Why choose our zirnano Ceramic Beads?

Higher Cleanliness

Zirnano ceramic beads are mede by the special technology,all the

ceramic beads are screened more than

six times and blow-cleaning under high temperature,which provides

higher clearliness and ensures it to be

work normally in humid weather;

More competitive price/performance ratio

Zirnano ceramic beads has almost the same particle size

distribution and blasting effect as the one of Zirblast,

while price is more competitive,since our plant located in mountain

areas,the environmental cost and labor

cost is cheaper.

Stable quality & Prompt delivery

Our ceramic beads is made by high quality zircon sand according to

stricter formula ratio,all the shipment will

be sampled and tested before loading. Equipped with the most

advanced production line and management

system,we can delivery the goods in time.

Stable suppliers of famous company

We are the stable supplier of Kumichel,Samsung

Electronics,Foxconn...

5. Questions and Answers:

Q: Are you manufacturer of ceramic beads?

A: Yes,our ceramic beads plant loacted in Shanxi,China

Q:How to place one order?

A:Please click one of our products,then send us one inquiry email,

we will reply you immediately after receiving it.

Q: We use galss beads 150# for stainless steel blasting in the

past,can I use ceramic beads to replace it?

A: Yes,ceramic beads B120 (63-125μm) can replace galss beads 150#

to blast stainless steel products,it will

achieve smooth bright satin finish.

Q: Which specification is more popular?

A: Ceramic beads B40,B60,B120,B205 is the popular specification.

Q:How about the delivery method?

A: If order quantity less than 100kgs,delivery by Air Express is

the most quick and reasonable way.

For order quantity more than 100kgs,we will delivery it by sea way.

Q: How about the precautions when I use the ceramic beads at first

time?

A:it is suggested to open 1/3 to 1/2 vest of dust collector,since

ceramic beads need the wind to be recycled in the

blasting process.

Q: Is ceramic beads recyclable?

A:Yes,ceramic beads is recyclable,it can be blasted 70-90 times in

the blasting process generally.

Q:Is it easy to be broken down in the blasting process?

A:No,it is not easy to be broken down,since it has dense crystal

structures and high mechnical strength.