1 kg Free sample ceramic abrasive blasting media B100 for titanium

alloy metal sandblasting

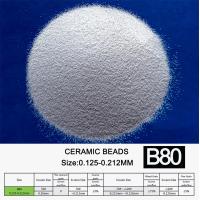

Description of ceramic abrasive blasting media

1 kg Free sample ceramic abrasive blasting media for titanium alloy

metal sandblasting

Ceramic Beads is ceramic abrasive sandblasting media, with very

fine micro structure featured strong wear resistance and high

toughness, and low-dust emission.

It does not contaminate the treated metal parts surface, especially

suited for metal and alloy tool cleaning and surface preparation

applications.

Comparing with steel shot, the ceramic beads can save energy and

preserve work parts because of its appropriate hardness and good

elasticity.

Specification of ceramic abrasive blasting media

Chemical Index:

| ZrO2 | 60-66% |

| SiO2 | 25-30% |

| Al2O3 | 7-13% |

Physical Index

| Processing: | Melting |

| Bulk Density: | 2.3g/cm3 |

| True Specific Gravity | 3.97 g/cm3 |

| Vickers Hardness: | 700 kg /mm2 |

Size

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 150-300 | 125-212 | 106-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 | Special sizes can be customized |

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 |

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

Application of ceramic abrasive blasting media

- 3C industry sandblasting: Computer shell, mobile phone middle

frame, built-in parts and USB Data cable plug blasting surface

treatment.

- Glass bottle & Tires Molds cleaning sandblasting

- Shot peening in automotive and aerospace industry.

- Metal parts surface treatment blasting finish, like Hard wares

parts, Pots, medical instrument, golf club, etc

Characteristics of Ceramic beads:

Ceramic beads is of iron free, no contamination or damage to

treated metal parts

Narrow particle sizes distribution and smooth spherical beads lead consistency in blasting treatment results from the

first part to the last.

Cost-effective compared to glass beads because of its high wear

resistance, 25 times better than glass beads.

Enhanced performance in dry air blast, wet blast as well as wheel

turbine blasting machines

If you need ceramic beads, pls feel free contact us for advisory

pre-sale service, best price, details, and samples, etc.

Caroline Cui