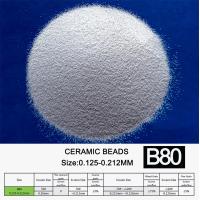

Blasting Media Ceramic Beads Glass Beads Steel Shot and Brown

aluminium oxide

Description

The ceramic beads is spherical shaped media with high mechanical

strength and high wear rates, also with

good round consistency and chemically stability.

The ceramic beads density creates higher impact speed making it a

good choice for deburring and peening.

And its good impact resistance leads it creating very little dust.

Ceramic blast processes produce a smooth bright satin finish.

Mainly used in sandblasting machine, including Manual & Automatic

sandblasting machine, Open type

sandblasting machine and Sandblasting machine room, and shot

peening equipment, etc.

Specification

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 |

| Specific Density | 3.85g/cm3 |

| Vickers Hardness | 700HV |

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

Features

Our ceramic beads is of top quality in China, and has below

features

1) Imported raw materials, High quality ceramic beads

Use Australia imported high-quality raw materials to produce

ceramic beads, high hardness, good elasticity and higher service

life.

2) Independent research and development

Complete product testing equipment and complete independent

intellectual property rights, as well as independent laboratories

and university cooperative laboratories in Beijing and

Shijiazhuang.

More importantly, we have years of continuous improvement in

R&D team.

3. Better cleanliness and sizes more concentration

We have our own particle sizes distribution standard, with more

concentration granules and can screen as per clients’ requirement.

4. High hardness, long life and good elasticity

The hardness of ceramic beads is high,and the deformation is small.

The hardness of ceramic sand can 700 HV, it ensures that ceramic

bead can be shot peened for high strength and high strength

structural parts. Small deformation ensures that the shape of the

projectile does not change during impact, and the spherical shape

of the ceramic sand improves the quality stability of the shot

peening of the part.

Application

1) 3C products - Sandblasting Finishing

Alloy shell, middle frame and built-in parts of computers, mobile

phones, cameras, etc. - sandblasting finishing

Clean burrs to form film-light decorative or fine reflective

surface, on alloy workpiece such as mobile phone to achieve

different reflection or matte.

2) Kitchen Industry-Sandblasting finishing

Stainless steel cutlery and kitchen utensils sandblasting finishing

3) Golf club - Sandblasting finishing

Golf club & ball head alloy surface treatment Sandblasting

finishing

4) Casting and forging parts, welded parts, heat-treated parts -

Sandblast Cleaning

Clean all the dirt on the surface of the alloy workpiece, micro

burrs, improve the flatness and smoothness of the workpiece, and

expose to uniform metallic color, achieving smooth and

non-reflective requirements on surface.

5) Pipeline - Sandblast Cleaning

Metal pipes such as copper pipes and steel pipes are cleaned and

polished on the inner and outer walls.

6) Molds - Sandblast cleaning

Cleaning of molds of glass bottles, tires, etc., rust, dirt and

impurities.

7) Electroplating, painting, anode-Surface Pretreatment

Electroplating, painting, anode, Teflon, rubber, plastic,

traversing, metal, spray welding, gold plating, titanium plating,

etc., to remove dirt and increase product surface adhesion.

8) Hardware parts - Sandblasting to improve lubrication conditions

It can produce uniform and fine uneven surface on the surface of

the part, so that the lubricating oil can be stored, improve the

lubrication condition and reduce the noise.

1) Aerospace industry-Shot Peening

Suitable for aerospace engine components, aircraft landing gear,

gear transmissions, aero-engine blades, aircraft wing-shot peening

2) Automotive industry-Sandblasting reinforcement/ Shot Peening

Suitable for gearbox gears, automotive aluminum hubs, piston

components/shock absorbers, engine crankshaft sandblasting

reinforcement/shot peening

3) Machinery, Medical Instrument - Sandblast finishing/shot peening

The overall sandblasting and polishing, finishing, restore the

natural color of the metal, enhance the visual effect and texture,

and also shot peening reinforcement to improve its worklife.

Applicable equipment

Manual sandblasting machine

Automatic sandblasting machine

Open type sandblasting machine

Sandblasting machine room

- In shot peening /shot blasting

Pneumatic shot blasting machine

Centrifugal shot blasting machine

CNC shot peening equipment

Wet shot blasting equipment

Contact Us

Besides ceramic beads, we also have other blasting media available

Glass beadsm steel shot, aluminum oxide etc.