Good Impact Resistance Ceramic Blasting Media Zirconia Bead

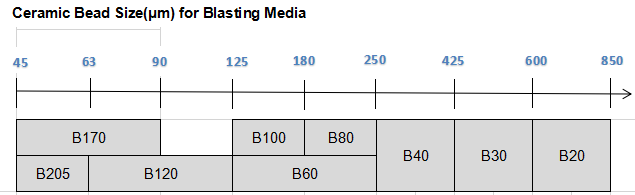

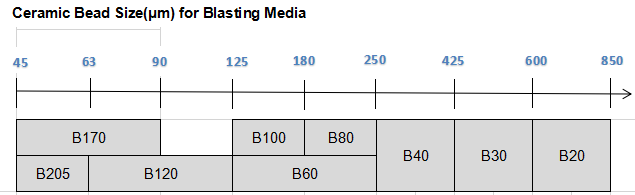

B20-B205 for Iphone Metal Surface Finish

1. Product Description of Ceramic Blasting Media Zirconia Bead

B20-B205

Ceramic bead is made by high quality zirconium sand in one

electrical furnace under high temperature

over 2000 degrees through special technology,then made into

different micro beads.

Ceramic beads and glass beads are two popular blasting media,both

has the round solid shape and no

ferrous containmation to the treated workpieces, while glass beads

has high breakdown rate and will generate

high dust, it has the hidden danger of silicisis to the operator, people also have to refuel new galss

beads because

galss beads has high consumption rate,then the final blasting effect is not so consistent as the one of

ceramic beads.

Therefore ceramic beads can replace the glass beads where one clean

and high consistent blasting effect is required.

2. Main Technical Data of Ceramic Bead Blasting

| ZrO2 | SiO2 | Al2O3 |

| 60-66% | 25-30% | 7-13% |

| Vicker Hardness | True Specific Gravity | Bulk Density |

| ≥700 HV | ≥3.85 g/cm3 | 2.3g/cm3 |

3. Main Features of Ceramic Bead Blasting

High Hardness,small deformation

Low breakdown rate,long service life

Low dust levels,good blasting sight

No ferrous contamination to the treatment surface

Few damage to the blasting equipment

No hideen danger of silicosis

4. Main Application of Ceramic Beads

Surface Finish for 3C products,medical instrument,golf club etc.;

Surfae cleaning for metal pipes,mechnical components;

Mold cleaning for glass molds,plastic molds,dies,casting etc;

Pre-treatment before plating&anode treatment

5. The comparasion between Ceramic Beads and Glass Beads

| Item | Ceramic Blasting Beads | Glass Beads |

| Chemical Index | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% | SiO2:>65%,Na2O<14.0%

CaO>8.0%,MgO>2.5%

Al2O3 0.5-2.0% Fe2O3:0.15% |

|

|

| Vickers Hardness | ≥700 HV | ≥560HV |

| True Specific Gravity | ≥3.85 g/cm3 | ≥2.5g/cm3 |

| Bulk Density | ≥2.3g/cm3 | ≥1.5g/cm3 |

| Particle Size | 0.04-0.85mm | 0.045-0.85mm |

| Usage | Blasting Media | Blasting Media |

| Ferrous Contamination | No Ferrous | No Ferrous |

| Dust Pollution | Little | Large |

| Recyclable Times | Multiple | One time or twice |

| Power consumption | Low | Low |

| Service Life | Long | 1/25 of ceramic beads |

| Equipment Wear Rate | Low | Low |

| Blasting Effect | High finish

No discoloration | High finish

White discoloration |

6. Why choose us

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning

under high temperature,

which provides higher clearliness and ensures it to be work

normally in humid weather;

More concentrated particle size distribution

B170(0.045-0.090μm),B205(0.045-0.063μm) is more concentrated than

the other one(0-0.063μm) from

other company,which will achieve better blasting effect.

High price/performance Ratio

Our factory is located in the mountain area,where has the lower

production cost and environmental cost,

So price is more competitive.