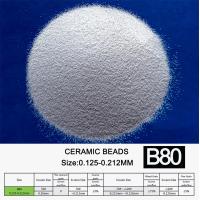

60HRC Zirconia Mircoblast Beads Ceramic Blasting Media B120 B170

B205 B400 B505 for Aluminium Parts

1. Product Description of Ceramic Bead Blasting Media

Ceramic Blasting Media is also called as ceramic beads,zirconia

sand, it is one clean blasting media

with extremely fine micro-structure, having the outstanding

features of good impact strength and toughness.

It is especially suitable for metal surface finish to delivery one

smooth and uniform blasting effect.

Ceramic Beads has the medium density,it is able to make up the

upper and lower limit sandblasting blind

area compared with glass beads and steel shot. It can replace glass

beads where one clean working

condition is required,also replace steel shot where one ferrous

contamination is not allowed.

In a word,it is one popular blasting media in many applications.

2. Main Technical Data of Ceramic Bead Blasting Media

| Commodity Name | Chemical Index | Physical Index |

Ceramic Bead Blasting Beads | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% | Vickers Hardness ≥700 HV

Bulk Density≥2.3g/cm3

True Gravity: 3.85g/cm3

Process: Melting |

|

|

| Particle Size |

| B20: 0.600-0.850mm | B120:0.063-0.125mm |

| B30:0.425-0.600mm | B150:0.000-0.125mm |

| B40:0.250-0.425mm | B170:0.045-0.090mm |

| B60:0.150-0.300mm | B205:0.000-0.063mm |

| B80:0.125-0.212mm | B400:0.030-0.063mm |

| B100:0.106-0.180mm | B505:0.010-0.030mm |

3. Main Applications of Ceramic Beads

Surface Cleaning for glass,plastic ,rubber and die casting parts;

Surface finish for light metal such as aluminium alloy,magnesium

alloy,titanium alloy;

Surface Preparation before electroplating& anodizing;

Surface finish for parts of aluminium,stainless steel...

4. Precautions for Using Ceramic Beads

When using ceramic beads for the first time, please kindly open 1/3

to 1/2 vest of dust collector,

Since ceramic beads need the wind to be recycled in the blasting

process.

Also Please kindly note that it can be multiple recycled.

The service life of ceramic beads is about 20-30 times than the one

of glass beads.

5. Blasting Effect of Ceramic Beads B505 Blasting effect