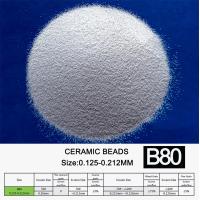

Ceramic blasting media B80, B100 of ZrO2 62% Factory supply

DESCRIPTION

Ceramic beads are obtained from fusion of zorcon sand and made into

micro beads, using as blasting media for blast cleaning and surface preparation. Ceramic media for deburring is a high quality zirconia based blast media with a very slow

breakdown rate, and durable, offering effective cleaning power with no surface

contamination to deliver a smooth satin finish.

Ceramic abrasive blasting media is durable, not easy to break, high in price but low in cost when

waste and disposal costs are included.

SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

Sizes

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

FEATURES

(1) Surface treatment consistency

Consistency of metallic light, the blasting strength is as good as

steel balls processing effect, much higher than the glass beads

strength. And can achieve adequate metal depth.

(2) Environmental Friendly

Low crushing rate, no dust, uniform particle size, high wear

resistance, re-elasticity, no hidden danger of silicosis, it is

harmless to the human body.

(3) Low equipment loss

Ceramic sand has smooth surface, high sphericity, good elasticity

and low wear, can protect the equipment, whether it is dry spray or

wet spray.

APPLICATION

- Ideal for impact finishing operations involving both manual and

automated machinery, where consistency of finish is important.

- Suitable for blasting the surface of all kinds of steel, aluminum

and other non-ferrous alloys to remove oxide, rust, sand, coatings

and burrs.

- Clean many industrial parts such as molds and dies, engine parts,

turbine machinery components, welded steel components, forged and

casted metals.

- Used for surface finishing applications when a satin metallic

surface is required with higher roughness

- Ceramic beads are easy to handle in all categories of air or wet

pressure blasting equipment including pneumatic blasting rooms.

- Also well suited for working in most kinds of wheel turbine

blasting machines.