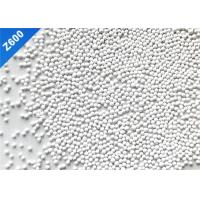

Ceramic Shot Peening Z600 Z425 Z300 Z210 For Automotive and

Aerospace Industry

1. Product Description of Ceramic Shot Peening

Ceramic shot peening selects the high quality imported zircon sand

as main material,then fused in an

electric arc furnace under high temperature over 2000

degrees,finally made into different beads according

to AMS standard.

Ceramic shot peening is also round solid beads,while it has higher

sphericity and more concentrated

particle size compared with ceramic beads.Then it is more

expensive.

2. Main Technical of Ceramic Shot Peening

Ceramic Beads | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% | Vickers Hardness ≥700 HV

Bulk Density≥2.3g/cm3

True Gravity: 3.85g/cm3

Process: Melting |

|

|

| Particle Size for Ceramic Shot Peening |

| Z100: 100-150μm | Z150: 150-210μm |

| Z210: 210-300μm | Z300: 300-425μm |

| Z425:425-600μm | Z600: 600-850μm |

| Z850: 850-1180μm | ./ |

| Remark: Special specification can be customized. |

3. Main Applications of Ceramic Shot Peeing

Manufacturing and maintenance of aerospace equipment such as

titanium alloy materials

Automotive industry, such as the anti-fatigue and strengthening

treatment for shock absorber spring

Turbine industry such as anti-fatigue treatment and strengthening

treatment on the surface of turbine blades

4. The advantages of Ceramic Shot Peening

High hardness,smooth surface;

High strength and good impact resistance;

Small deformation to ensure the accuracy of the treatment;

Low breakdown rate;

No contamination to the treatments;

More consistent surface finish.

5. Packages of Shot Peening

25kg barrel+ Pallet;

2*12.5kg barrel+ Pallet;

25kg barrel+ Wooden Case;

Special package can be customized.