Iron-free Ceramic micro beads B170 blasting media for alloy surface

finishing

DESCRIPTION

Ceramic bead blasting is zirconia-based blasting media, obtained in

special production process and unique formula. ZrO2 62-65%, HS code

690919. The beads are no dust, durable and efficient, offering

consistent surface finishing, are new eco-friendly blasting

material, widely used for blast cleaning and surface preparation.

Ceramic blasting beads mainly used for debluring and blast

finishing in mobile phone middle frames and other 3C products, also

in glass bottles molds cleaning, golf clubs surface finishing,

painting surface pretreatment and shot peening in aerospace

industry, automotive industry and medical instrument.

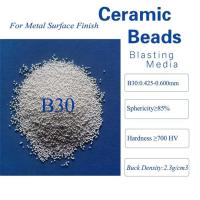

SPECIFICATION

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 | Special sizes can be customized |

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 |

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

FEATURES

1. High hardness and good impact resistance to enable Efficient and

durable blasting

2. Consistent Surface Finishing

3. No contaminating to the treated material

4. Very low dust emission, safe and healthy for workers

5. High toughness to ensure media stability over numbers of

blasting cycles

6. Not break down, extremely cost effective

APPLICATIONS

Removal of carbon deposits and other impurities from glass making

and rubber tire molds, without damaging the surface or critical

edges. Deburring thin gaskets.

Cleaning, sanitizing and surface finishing of fabricated stainless

steel items for food and pharmaceutical industries. Blasting gives

stainless steel a satin grey touch

Medical implant and instrument surface finishing.

Work pieces blasted with ceramic beads are a lot less prone to

fingerprints and other handling stains than those blasted with

glass beads and stay looking good a lot longer.

APPLICABLE EQUIPMENT

Suitable sand blasting machine:

Manual type series:

Manual closed type blasting machine, manual cart rotary blasting

machine, double gun double station manual blasting machine, manual

(automatic) roller dual-purpose blasting machine, manual closed

pressure

Automatic series of sand blasting machine:

Automatic closed pressure blasting machine, automatic conveying

type blasting machine, crawler type blasting machine, automatic

turntable blasting machine, automatic turntable continuous pressure

blasting machine, automatic conveying

Open type series of sand blasting machine:

Crankshaft inner wall automatic sand blasting machine

Blasting room series:

Pneumatic conveying type blasting room, mechanical conveying type

blasting room, etc.

CONTACT US

No matter you’re the end users, blasting service suppliers,

sandblasting equipment dealers or ceramic beads and other blasting

abrasive distributors, welcome to contact us. More details of

ceramic bead blasting, updated prices and samples will be

available.

Caroline Cui