B60 Ceramic Beads Media with RoHS certificates for Abrasive flow

Deburring

Description of Ceramic beads for deburring

Ceramic blasting beads is made of imported zircon sand as a raw

material and melted in Ore furnace in

temperature above 2000℃,and then blow into micro beads. It is an

efficient and environmentally friendly

sand blasting media. Based on the performed tests on Ceramic beads

samples by SGS, the result if

Cadmium, lead, Mercury, Hexavalent chromium, PBBs, PBDEs do not

exceed the limit as set by

RoHS Directive (EU)

| Technical Data |

| Components | Content | CAS No. | EC No. |

| ZrO2 (Zirconium dioxide) | 60-68% | 1314-23-4 | 215-227-2 |

| SiO2 (Silicon dioxide) | 25-30 | 60676-86-0 | 262-373-8 |

| Al2O3 (Aluminum oxide ) | 7-13% | 1344-28-1 | 215-691-6 |

| Manufacturing Method | Melting in above 2000℃ furnace |

| True Density | 3.85 g/cm3 |

| Bulk Density | 2.3g/cm3 |

| Vicker Hardness | 700HV |

| Sizes for Sand Blasting |

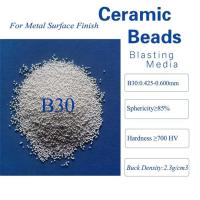

| Bead Size | Size range | Bead Size | Size range |

| B20 | 0.60-0.85 mm | B120 | 0.063-0.125 mm |

| B30 | 0.425-0.60 mm | B125 | 0.000-0.125 mm |

| B40 | 0.24-0.425 mm | B170 | 0.045-0.090 mm |

| B60 | 0.125-0.25 mm | B205 | 0.000-0.063 mm |

| B80 | 0.18-0.25 mm | B400 | 0.030-0.063 mm |

| B100 | 0.125-0.18 mm | B505 | 0.000-0.030 mm |

| Sizes for Shot Peening |

| Z850 | 0.85-1.18 mm | Z210 | 0.21-0.30 mm |

| Z600 | 0.6-0.85 mm | Z150 | 0.15-0.21 mm |

| Z425 | 0.425-0.60 mm | Z100 | 0.10-0.15 mm |

| Z300 | 0.30-0.425 mm | | |

Features of Ceramic beads for deburring

1. Ceramic beads has long service life and high cost performance:

The life of ceramic beads is more than 30 times that of glass

beads. Ceramic sand will not wear, only a small amount will be

broken into pieces, and the broken ceramic beads will still

maintain the original size, shape and hardness. and smooth surface,

this is enough to recycle.

2. Ceramic beads does not produce dust. This is enough to

effectively reduce the dust content and final waste in the working

environment, which can effectively protect the environment from

pollution and pose no harm to workers.

3. Ceramic beads has high hardness, long service life, good

elasticity and low wear, which can effectively reduce the number of

replacement materials and reduce the cost of workers. Whether it is

used in dry blasting, wet blasting or shot blasting, ceramic sand

can bring high efficiency.

Application of Ceramic beads for deburring

Aluminum alloy work pieces inner holes abrasive flow deburring

Metal deburring is mainly to deal with metal surfaces and internal

hole burrs. The burrs on the workpiece are caused by plastic

deformation during the cutting process, and some are the flashing

of the castings, the forgings, and some of the materials extruded

by the welding.

Surface deburring is not difficult, then how about the inner hole

deburring?

How to deburr the inner hole for aluminum alloy workpieces with

many inner holes and intersecting holes?

1. Difficulties in deburring the inner hole of aluminum alloy

workpiece

The heat resistance and acid resistance of aluminum alloy

workpieces are not too high, and they are not suitable for

compression. These features eliminate many deburring methods.

Moreover, it can be seen that these burrs are mainly concentrated

near the intersecting holes of the inner hole, and the ultrasonic

deburring grinding head can not be found there, and it is barely

used, and may not be cleaned. Moreover, in order to maintain the

precision of the workpiece, we must also control the polishing

margin within a reasonable range when removing the internal hole

burr.

Therefore, we must find a way to solve the inner hole, without loss

of precision, without damaging the workpiece, and environmentally

friendly deburring.

2. Ceramic beads abrasive flow is the most applicable deburring

ways of aluminum alloy inner hole

First of all, the abrasive flow is the most suitable process for

deburring the inner hole. Secondly, by adjusting the particle size

of the abrasive and the polishing time, we can control the

polishing allowance. From the enlarged detail view, after polishing

the abrasive flow, we no longer need to go through any treatment,

which not only solves the problem of internal hole burr, but also

improves the polishing effect of 2-3 grades on the original basis

of the workpiece. This is unique in all deburring processes.

Applicable sand blasting machine:

1. Manual type series

2. Automatic series

3. Open series

4. Sandblasting room type series