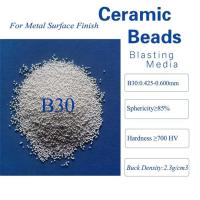

60-66% ZrO2 Zirconia Sand Ceramic Bead Blasting B170 B205 B400 B505

for Satin Metallic Surface Finish

1. Product Description of Ceramic Bead Blasting

Ceramic beads contains 60-66% ZrO2 ,its fine micro-structure

provides its characteristics of high hardness and

good elasticity and impact resistance,which is one iedal blasting

media in military and civilian fields.

2. The Main Technical Data of Ceramic Bead Blasting

| Main Index of Ceramic Bead Blasting |

| ZrO2 | SiO2 | Al2O3 |

| 60-66% | 25-30% | 7-13% |

| Vicker Hardness | True Specific Gravity | Bulk Density |

| ≥700 HV | ≥3.85 g/cm3 | 2.3g/cm3 |

| Particle Size |

| B20 | B30 | B40 |

| 600-850μm | 425-600μm | 250-425μm |

| B60 | B80 | B100 |

| 150-300μm | 125-212μm | 106-180μm |

| B120 | B170 | B205 |

| 63-125μm | 45-90μm | 0-63μm |

| B400 | B505 | / |

| 30-63μm | 0-30μm | / |

3. The comparation between Ceramic Sandblasting and Ceramic Shot

Peening

Ceramic Beads blasting media and ceramic shot peening has the same

chemical composition and

Properties,while they have different requirements in particle size

distribution and spherity.

Ceramic beads blasting is widely used to all kinds of steel,

aluminum ,light alloy,plastic products. While ceramic

shot peening is widely used in hard steel, titanium and aluminum

alloy to enhance the fatigue resistance.

4. Main Applications of Ceramic Bead Blasting Media

B20&B30:Surface finish for metal Surface;

B40:Mold cleaning for glass bottles;

B60: surface cleaning for inner or outter wall of precision steel

pipes & stainless steel ;

B120: Surface finish for Golf head and artifical joint etc.

B170&B205: Surface finish for the metal surface of 3C

Products,built-in parts,as well as its accessories.

5. Why choose Zirnano Ceramic Beads?

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning

under high temperature,

which provides higher clearliness and ensures it to be work

normally in humid weather;

More Competitive price/performance Ratio

Our ceramic beads plant is located in mountain area,there is lower

labor cost & environmental cost,then the

product cost is lower and more competitive than the one of others’

plants.

More stable quality

Our ceramic beads is made by high quality zircon sand according to

stricter formula ratio,all the shipment will

be sampled and tested before loading.

6. Precautions When Using Ceramic Beads for the first time

Please kindly open 1/3 to 1/2 vest of dust collector when using

ceramic bead for the first time,because ceramic beads

need the wind to be recycled. This is different from glass beads,

when using galss beads,the vest of dust collector is

sealed completely.