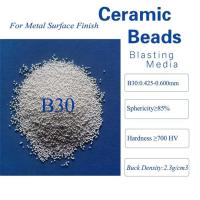

| Title | ZrO2 62%-66% Ceramic Blasting Beads

B20, B30, B40, B60, B80, B100, B120, B170, B205, B400, B505 |

| Product Name | Ceramic Beads Blasting Media/ Ceramic Media Shot Peening |

| Technical Data |

| Components | Content | CAS No. | EC No. |

| ZrO2 (Zirconium dioxide) | 60-68% | 1314-23-4 | 215-227-2 |

| SiO2 (Silicon dioxide) | 25-30 | 60676-86-0 | 262-373-8 |

| Al2O3 (Aluminum oxide ) | 7-13% | 1344-28-1 | 215-691-6 |

| Manufacturing Method | Melting in above 2000℃ furnace |

| True Density | 3.85 g/cm3 |

| Bulk Density | 2.3g/cm3 |

| Vicker Hardness | 700HV |

| Sizes for Sand Blasting |

| Bead Size | Size range | Bead Size | Size range |

| B20 | 0.60-0.85 mm | B120 | 0.063-0.125 mm |

| B30 | 0.425-0.60 mm | B125 | 0.000-0.125 mm |

| B40 | 0.24-0.425 mm | B170 | 0.045-0.090 mm |

| B60 | 0.125-0.25 mm | B205 | 0.000-0.063 mm |

| B80 | 0.18-0.25 mm | B400 | 0.030-0.063 mm |

| B100 | 0.125-0.18 mm | B505 | 0.000-0.030 mm |

| Sizes for Shot Peening |

| Z850 | 0.85-1.18 mm | Z210 | 0.21-0.30 mm |

| Z600 | 0.6-0.85 mm | Z150 | 0.15-0.21 mm |

| Z425 | 0.425-0.60 mm | Z100 | 0.10-0.15 mm |

| Z300 | 0.30-0.425 mm | | |

| Application in Sand Blasting |

| 1) 3C products - Sandblasting Finishing |

| Alloy shell, middle frame and built-in parts of computers, mobile

phones, cameras, etc |

| Clean burrs to form film-light decorative or fine reflective

surface, on alloy workpiece such as mobile |

| phone to achieve different reflection or matte. |

| 2) Kitchen Industry-Sandblasting finishing |

| Stainless steel cutlery and kitchen utensils sandblasting finishing |

| 3) Golf club - Sandblasting finishing |

| Golf club & ball head alloy surface treatment Sandblasting

finishing |

| 4) Casting and forging parts, welded parts, heat-treated parts -

Sandblast Cleaning |

| Clean all the dirt on the surface of the alloy workpiece, micro

burrs, improve the flatness and |

| smoothness of the workpiece, and expose to uniform metallic color,

achieving smooth and |

| non-reflective requirements on surface |

| 5) Pipeline - Sandblast Cleaning |

| Metal pipes such as copper pipes, steel pipes are cleaned and

polished on the inner and outer walls. |

| 6) Molds - Sandblast cleaning |

| Cleaning of molds of glass bottles, tires, etc., rust, dirt and

impurities. |

| 7) Electroplating, painting, anode-Surface Pretreatment |

| Electroplating, painting, anode, Teflon, rubber, plastic,

traversing, metal, spray welding, gold plating, |

| titanium plating, etc., to remove dirt and increase product surface

adhesion. |

| 8) Hardware parts - Sandblasting to improve lubrication conditions |

| It can produce uniform and fine uneven surface on the surface of

the part, so that the lubricating oil can |

| be stored, improve the lubrication condition and reduce the noise. |

| Application in Shot Peening |

| 1) Aerospace industry-Shot Peening |

| Suitable for aerospace engine components, aircraft landing gear,

gear transmissions, aero-engine |

| blades, aircraft wing etc.. |

| 2) Automotive industry-Sandblasting reinforcement/ Shot Peening |

| Suitable for gearbox gears, automotive aluminum hubs, piston

components/shock absorbers, engine |

| crankshaft sandblasting reinforcement/shot peening |

| 3) Machinery, Medical Instrument - Sandblast finishing/shot peening |

| The overall sandblasting and polishing, finishing, restore the

natural color of the metal, enhance the |

| visual effect and texture, and also shot peening reinforcement to

improve its worklife. |