Ceramic Beads Blasting Media Zirconia Sand B60 150-300μm for

Stainless Steel Surface Finish

1. Product Description of Ceramic Bead Blasting

Ceramic Beads selected the high quality zircon sand as main raw

materials,then fused in electric furnace,finally

made into different sizes through special technology.

It is one clean blasting media with lower dust in the whole

blasting process,it is also one more efficient abrasive ,

whose service life will be prolonged 20-30 times compared with

glass beads. It is widely used in many applications

where one clean and more consistent blasting effect is required.

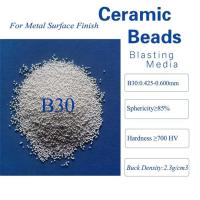

2. The Main Technical Data of Ceramic Bead Blasting

| Commodity | Main Chemical Index | Main Physical Index |

Ceramic Bead Blasting | ZrO2 60-66% | Bulk Density: 2.3g/cm3 |

| SiO2 25-30% | True Specific Gravity: 3.85 g/cm3 |

| Al2O3 7-13% | Vickers Hardness: 700 kg /mm2 |

Particle Size

| B20: 0.600-0.850mm | B100: 0.106-0.180mm |

| B30: 0.425-0.600mm | B120: 0.063-0.125mm |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm |

| B60: 0.150-0.300mm | B205: 0.000-0.063mm |

| B80: 0.125-0.212mm | B400: 0.030-0.063mm |

| Remark: Special specification can be customized |

3. The advantages of Ceramic Bead Blasting

More Consistent Blasting Effect

Ceramic Beads has lower breakdown rate, only few beads will be

broken,the non-broken ceramic beads will

maintain its original shape and properties to achieve more

consistent blasting effect.

Low treatment costs for solid waste

There is little dust generated in whole blasting process, so little

solid waste to be treated,finally save the production

cost.

Longer service life

Ceramic beads has fine microstructure, lower breakdown rate,it is

not easy to be broken in the whole blasting

process, the non-broken one will still maintain its original shape

and properties, it can be reused for many cycles.

No hidden danger of Silicosis

Ceramic beads will generate little dust in the whole blasting

process,there is no hidden danger of silicosis to the

operator.

4. Main Applications of Ceramic Bead Blasting:

Surface Blasting for casting and forging parts, welded parts,

heat-treated parts etc;

Surface cleaning for steel pipe,metal pipes;

Surface finish for medical instruments and golf head etc

Surface Blasting for hardwares,mechnical parts etc

6. Package of Ceramic Beads:

25kg barrel+ pallet or 2*12.5kg barrel + Pallet

Special package can be customized.

7. Cautions for Blasting :

Ensure the sufficient ceramic beads in the blasting machine;

The workers must wear the protective equipments before work.

No less than two workers when the blasting machine is working.

Please check the gas storage tank, pressure gauge and safety valve

regularly;

It is necessary to start the ventilation and dust removal equipment

five minutes before working.

It is prohibited to work when the above equipment can not work

properly.

Please open the air valve slowly and keep the normal pressure.