Ceramic Beads Blasting Media B170, B205,B400,B505 for Iphone Metal

Surface Finish

1. Product Description of Ceramic Bead Blasting Media

Ceramic beads is also called as zircon sand,it selected the high

quality zirconium sand as main raw

material,then fused in electric furnace at high temperature,finally

made into different mirco beads by

special technology.

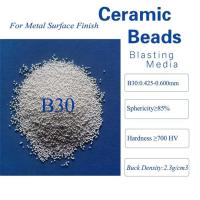

2. Main Technical Data of Ceramic Bead Blasting Media

| Item | Ceramic Blasting Beads | Particle Size |

| Chemical Index | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% | B20:0.600-0.850mm | B120:0.063-0.125mm |

| B30:0.425-0.600mm | B150:0.053-0.106mm |

| B40:0.250-0.425mm | B170:0.045-0.090mm |

| Mohs Hardness | ≥700 HV | B60:0.150-0.300mm | B205:0.000-0.063mm |

| True Specific Gravity | ≥3.85 g/cm3 | B80:0.125-0.212mm | B400:0.030-0.063mm |

| Bulk Density | ≥2.3g/cm3 | B100:0.106-0.180mm | B505:0.010-0.030mm |

3. Main Features of Ceramic Beads Blasting Media

High hardness,good elasticity and smooth surface,then ceramic beads

can be rebounded in multi-angles,

especially suitable for metal surface finish;

Longer service life and lower consumption,ceramic beads has tiny

microstructure,it is not easy to be broken

in the blasting process,service life can be prolonged 25-30 times

than the one of glass beads in wet blasting.

Lower breakdown rate

People do not need to refuel the ceramic beads frequently,the

quantity and the shape of ceramic beads

almost keep the same in the blasting process, which will achieve

more consistent and nice shiny smooth

blasting effect than the one of glass beads.

Solid round shape and white color

There is little damage and no ferrous contamination to the

treatment surface due to its solid round shape

and white color.

Little dust generation

Ceramic Beads will generate little dust in blasting process,which

will provide better blasting visual and no

hidden danger of silicosis.

4. Main Applications of Ceramic Beads Blasting

In Blasting Applications:

Surface Finish in Aerospace industry such as the structural

materials of aluminum alloy, titanium alloy,

aluminum alloy, high temperature alloy etc.

Anti-fatigue treatment and strengthening treatment on the surface

of turbine blades and suspension

spring in turbine industry and automotive industry

Metal surface finish for mechanical parts, cylinder heads, surgical

instruments, prosthetics, golf heads,

artificial joints, springs, gears, glasses frame etc.

Deburring forcircuit board , plastic parts at low temperature in

plastic and electronics industries:

Mould cleaning and maintenance in mould industry such as glass

moulds, tire manufacturing.

In Shot Peening Applications:

Shot peening in aviation and automotive industries;

Shot peening in nuclear and chemical equipments.

5. Precautions When Using Ceramic Beads for the first time

Please kindly open 1/3 to 1/2 vest of dust collector when using ceramic bead for the first time,because ceramic

beads need the wind to be recycled. This is different from glass beads, when using galss beads,the vest

of dust

collector is sealed completely.

6. Which kind of material are suitable for being treated by ceramic

beads?

Stainless steel parts;

Aluminum and aluminum alloy parts:

Copper partsMagnesium alloy parts;

Titanium alloy parts;

Plastic parts etc.