Size B60 Ceramic Beads Blasting Media Long Service Life 20-30 times

of glass beads

DESCRIPTION

Ceramic blasting beads is a high grade sandblasting media of proper

density (with bulk density 2.3g/cm3) and

good hardness (700HV, Mohs 7) blasting media.

It can be recycled in the sandblasting process, and with long

service life, about 30 times that of glass beads.

| Technical Data |

| Components | Content | CAS No. | EC No. |

| ZrO2 (Zirconium dioxide) | 60-68% | 1314-23-4 | 215-227-2 |

| SiO2 (Silicon dioxide) | 25-30 | 60676-86-0 | 262-373-8 |

| Al2O3 (Aluminum oxide ) | 7-13% | 1344-28-1 | 215-691-6 |

| Manufacturing Method | Melting in above 2000℃ furnace |

| True Density | 3.85 g/cm3 |

| Bulk Density | 2.3g/cm3 |

| Vicker Hardness | 700HV |

| Sizes for Sand Blasting |

| Bead Size | Size range | Bead Size | Size range |

| B20 | 0.60-0.85 mm | B120 | 0.063-0.125 mm |

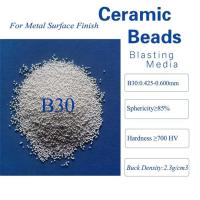

| B30 | 0.425-0.60 mm | B125 | 0.000-0.125 mm |

| B40 | 0.24-0.425 mm | B170 | 0.045-0.090 mm |

| B60 | 0.125-0.25 mm | B205 | 0.000-0.063 mm |

| B80 | 0.18-0.25 mm | B400 | 0.030-0.063 mm |

| B100 | 0.125-0.18 mm | B505 | 0.000-0.030 mm |

| Sizes for Shot Peening |

| Z850 | 0.85-1.18 mm | Z210 | 0.21-0.30 mm |

| Z600 | 0.6-0.85 mm | Z150 | 0.15-0.21 mm |

| Z425 | 0.425-0.60 mm | Z100 | 0.10-0.15 mm |

| Z300 | 0.30-0.425 mm | | |

FEATURES

1. Ceramic beads has long service life and high cost performance:

The life of ceramic beads is more than 30 times that of glass

beads. Ceramic sand will not wear, only a small amount will be

broken into pieces, and the broken ceramic beads will still

maintain the original size, shape and hardness. and smooth surface,

this is enough to recycle.

2. Ceramic beads does not produce dust. This is enough to effectively reduce the dust content and final

waste in the working environment, which can effectively protect the

environment from pollution and pose no harm to workers.

3. Ceramic beads has good hardness, good elasticity and low wear, which can effectively reduce the number of replacement materials

and reduce the cost of workers. Whether it is used in dry blasting,

wet blasting or shot blasting, ceramic sand can bring high

efficiency.

APPLICATION

- 3C industry sandblasting: Computer shell, mobile phone middle

frame, built-in parts and USB Data cable plug blasting surface

treatment.

- Glass bottle & Tires Molds cleaning sandblasting

- Shot peening in automotive and aerospace industry.

- Metal work pieces surface treatment blasting finish, like Hard

wares parts, Pots, medical instrument, golf club, etc

APPLICABLE EQUIPMENT

Ceramic beads is mainly used as sandblasting media, applicable for

all kinds of blasting machine.

How to choose the sandblasting machine in using ceramic beads as

blasting media?

- To see the size of the work piece, then decide to choose the box

sandblasting machine, mobile sandblasting machine, or automatic

sandblasting machine. Ceramic beads blasting media is applicable

for all these sandblasting machines.

- To see the shape of the work piece, choose the specifications of

the sandblasting machine, generally under 1 meter have fixed

specifications, if especially large, to choose the open blasting

machine.

- Surface treatment requirements, check to use of dry blasting or wet

blasting, if dry blasting, there will be many choices of abrasive,

wet blasting is generally glass beads. Ceramic beads usually choose

dry blasting machine.

- Some of the accessories of sandblasting machine to be familiar

with, sandblasting gun and sandblasting gloves are often to change

things even the ceramic beads is of low wear assistance.

- Sandblasting process automatic blasting machine is suitable for:

portable computer case, heat sink, glass, iron plate, iron,

sandwich baking tray, audio panel, stone, wrench, aluminum pot,

bakelite products, etc.

The gas washing separator is the most suitable recycling equipment

for ceramic BEADS, and the screening machine and cyclone separator

can also be used for ceramic beads recycling.

The mixture enters the upper part of the gas divider and is

conditioned to form a layer for recovery.

The good ceramic beads does not deviate from the direct drop. The

gas generated by the dust collecting fan blows away the broken

beads and dust upwards. The dust is discharged into the dust

collector along with the air flow, and the broken ceramic beads

falls into the trash can due to the expansion of air. .