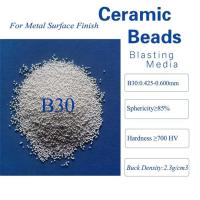

Ceramic Bead Blasting B20-B60,B120-B205 for Stainless Steel Surface

Finish

1. Product Description of Ceramic Bead Blasting Media

Ceramic bead is one clean blasting material,it selected the

imported zirconia sand as main raw material,

then fused in high temperature electric furnace,finally made into

different micro beads by unique blowing

technology.

Ceramic Beads has the excellent impact strength and toughness due

to its tiny microstructure,there is

no ferrous contamination to the surface treatment,so it is one

ideal blasting media for metal surface finish

as well as light alloy and stainless steel.

2. Main Technical Data of Ceramic Bead Blasting Media

| Item | Ceramic Blasting Beads | Particle Size |

| Chemical Index | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% | B20:0.600-0.850mm | B120:0.063-0.125mm |

| B30:0.425-0.600mm | B150:0.053-0.106mm |

| B40:0.250-0.425mm | B170:0.045-0.090mm |

| Mohs Hardness | ≥700 HV | B60:0.150-0.300mm | B205:0.000-0.063mm |

| True Specific Gravity | ≥3.85 g/cm3 | B80:0.125-0.212mm | B400:0.030-0.063mm |

| Bulk Density | ≥2.3g/cm3 | B100:0.106-0.180mm | B505:0.010-0.030mm |

3. Main Features of Ceramic Beads Blasting Media

High hardness,good elasticity and smooth surface,then ceramic beads

can be rebounded in multi-angles,

especially suitable for metal surface finish;

Longer service life and lower consumption,ceramic beads has tiny

microstructure,it is not easy to be broken

in the blasting process,service life can be prolonged 25-30 times

than the one of glass beads in wet blasting.

Lower breakdown rate

People do not need to refuel the ceramic beads frequently,the

quantity and the shape of ceramic beads

almost keep the same in the blasting process, which will achieve

more consistent and nice shiny smooth

blasting effect than the one of glass beads.

Solid round shape and white color

There is little damage and no ferrous contamination to the

treatment surface due to its solid round shape

and white color.

Little dust generation

Ceramic Beads will generate little dust in blasting process,which

will provide better blasting visual and no

hidden danger of silicosis.

4. Main Applications of Ceramic Beads Blasting

Surface Finish for 3C proudcts such as metal shell and built-in

parts of mobile phone,computer,camera as

well as its accessories: USB,power bank...

Surface cleaning for various molds such as glass-bottle molds,tire

molds,plastic molds as well as die-casting.

Surface Finish for light alloy such as magnesium alloy,aluminum

alloy, titanium alloy as well as stainless steel

Surface pretreatment before Electroplating, painting, anode

Sandblasting for hardwares,casting and forging parts, welded parts,

heat-treated parts

5. Precautions When Using Ceramic Beads for the first time

Please kindly open 1/3 to 1/2 vest of dust collector when using ceramic bead for the first time,because ceramic

beads need the wind to be recycled. This is different from glass beads, when using galss beads,the vest

of dust

collector is sealed completely.

6. Why Choose Us?

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning

under high temperature,which provides

higher clearliness and ensures it to be work normally in humid

weather;

More concentrated particle size distribution

B170(0.045-0.090μm),B400(0.030-0.063μm) is more concentrated than

the other one(0-0.063μm) from other

company,which will achieve better blasting effect.

More competitive price

Our plant is located in mountain area,which provides lower cost in

environmental protection and workers’ salary,

then the product price Is more competitive than the one of other

plants.

More flexible corporation model

No matter you are the distributor or final users,we will provide

the more flexible payment term and corporation model.