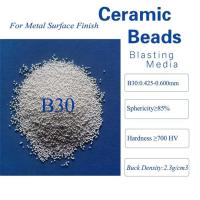

Zirconia Ceramic microbeads B505 for metal surface satin finish

DESCRIPTION OF CERAMIC BLASTING MICRO BEADS

Ceramic blasting micro beads, with ZrO2 60-68%, also calls zirconia

microbeads, are generally used

as blasting media for surface satin finish like debluring, matte

effect surface, and molds cleaning like rubber

and plastic moulds etc..

SPECIFICATION OF CERAMIC BLASTING MICRO BEADS

| Chemical Index | ZrO2 | SiO2 | Al2O3 |

| 60-65% | 25-30% | 7-13% |

| Typical Value | 62.20% | 26.10% | 9.05% |

| Bulk Density | 2.3g/cm3 |

| Specific Density | 3.85g/cm3 |

| Vickers Hardness | 700HV |

Sizes

B505:0.0.063MM

OTHER SIZES AVAILABLE

| B20 | B30 | B40 | B60 |

| 600-850µm | 425-6000µm | 0250-425µm | 125-250µm |

| B80 | B120 | B170 | B205 |

| 180-250µm | 63-125µm | 45-90µm | 0-63µm |

Special sizes available against clients’ requirement.

FEATURES OF CERAMIC BLASTING MICRO BEADS

Surface finish consistency

01 Low breakdown

With features of less abrasive breakdown and almost no dust

generation which in turn results in a cleaner working environment

and better operator visibility

Comparing with glass beads, ceramic bears is of low breakdown rates

up to 15:1 , thus enables it repeatable and consistent result to be

achieved.

02 Narrow particle size distribution

The more centralized granularity can make the objects surface more

uniform, and softer view in blasting process.

Contrast of Ceramic bead, glass beads and steel shot

| Index | Ceramic beads | Glass beads | Steel shot |

| Main components | ZrO2+SiO2 | SiO2+NaO2 | C+Si+Mn+S+P |

| Vickers hardness | ≈700HV | ≈560HV | ≈700HV |

| True density | 3.85g/cm³ | 2.6 g/cm³ | 7.8 g/cm³ |

| Particle size interval | 0.04-0.85mm | 0.045-0.85mm | 0.05-0.60mm |

| Particle shape | spherical | spherical | rounded corner |

| Dust pollution | very little | much | little |

| Metal pollution | no | no | yes |

| Number of cycles | multiple times | 1-2times | multiple times |

| service life | long | Low,1/20 of ceramic bead | long |

| power consumption | Low | Low | High |

| Equipment wear | Low | Low | High |

| Sandblasting effect | High finish, non-discoloration of workpiece | high finish, white glaze, | low finish,

blackened workpiece |

APPLICATION OF CERAMIC BLASTING MICRO BEADS

1) 3C products - Sandblasting Finishing

2) Aerospace industry-Blasting finishing

3) Automotive industry-sandblasting reinforcement

4) Kitchen Industry-Sandblasting finishing

5) Machinery, Medical Instrument - Sandblast finishing

6) Casting and forging parts, welded parts, heat-treated parts -

Sandblast Cleaning

7) Pipeline - Sandblast Cleaning

8) Molds - Sandblast cleaning

9) Electroplating, painting, anode-Surface Pretreatment

10) Hardware parts - Sandblasting to improve lubrication conditions

APPLICABLE EQUIPMENT

Suitable sand blasting machine:

Manual type series:

Manual closed type blasting machine, manual cart rotary blasting

machine, double gun double station manual blasting machine, manual

(automatic) roller dual-purpose blasting machine, manual closed

pressure

Automatic series of sand blasting machine:

Automatic closed pressure blasting machine, automatic conveying

type blasting machine, crawler type blasting machine, automatic

turntable blasting machine, automatic turntable continuous pressure

blasting machine, automatic conveying

Open type series of sand blasting machine:

Crankshaft inner wall automatic sand blasting machine

Blasting room series:

Pneumatic conveying type blasting room, mechanical conveying type

blasting room, etc.

Our Service

Free Samples -1kgs

Different blasting workpieces, Different requirements for ceramic

beads.

Our factory can provide consult solution, suggest the ceramic beads

sizes according to the workpiece you handle and provide 1kgs

ceramic beads samples for free.

OEM customize same ceramic beads with your samples or requirements.

Our factory has our own test lab., with high precision chemical and

particle size detection instruments. You can send ceramic beads

samples, then we will test and analysis it and customize same

ceramic beads with your samples or according to your customer

requirements.

Quality Guarantee

Guarantee our ceramic beads has no quality problems, and in case

any problems are found,

We accept return and/or exchange.