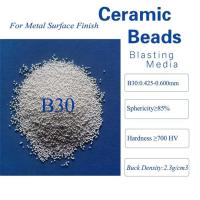

Ceramic Bead Blasting Zirconium Silicate Beads B20 B40 B60 B120

B170 B205 for Surface Cleaning

1. Product Description of Ceramic Bead Blasting Zirconium Silicate

Beads

Ceramic Bead is one clean and durable blasting media,it has smooth

surface,which will not damage the

original dimension of most treated parts. leaves a fine surface and

will not distort or change dimensions

of most parts.

2. The Simple Comparation between Ceramic Beads & Glass Beads

As we know,ceramic beads and glass beads has the similar solid

round shape,while they are different

two blasting media,hereby we just make a simple comparation as

below:

| Item | Ceramic Blasting Beads | Glass Beads |

| Chemical Index | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% | SiO2:>65%,

Na2O<14.0%

CaO>8.0%,MgO>2.5%

Al2O3 0.5-2.0% Fe2O3:0.15

|

|

|

| Vickers Hardness | ≥700 HV | ≥560HV |

| True Specific Gravity | ≥3.85 g/cm3 | ≥2.5g/cm3 |

| Bulk Density | ≥2.3g/cm3 | ≥1.5g/cm3 |

| Particle Size | 0.04-0.85mm | 0.045-0.85mm |

| Usage | Blasting Media | Blasting Media |

| Ferrous Contamination | No Ferrous | No Ferrous |

| Dust Pollution | Little | Large |

| Recyclable Times | 70-90 | 9-12 |

| %Breakdown | 1.2% | 10% |

| Equipment Wear Rate | Low | Low |

| Blasting Effect | Stain finish

No discoloration | High finish

White discoloration |

Seen from the above chart, ceramic beads is more durable and could

be recycled for 70-90times,while

glass beads only could be recycled for 9-12 times;Ceramic beads

also has quite low breakdown rate,

dust pollution and will provide no discoloration to the treatment

surface.

Therefore,ceramic beads can replace glass beads where a clean and

good blasting effect requires.

3. The particle size of ceramic bead blasting

Ceramic beads has wide particle size from micro size to the very

fine size,it is able to be matched

with various blasting equipment, detail particle size as below:

| Particle Size |

| B20 | B30 | B40 |

| 600-850μm | 425-600μm | 250-425μm |

| B60 | B80 | B100 |

| 125-250μm | 180-250μm | 125-180μm |

| B120 | B170 | B205 |

| 63-125μm | 45-90μm | 0-63μm |

4. Why Ceramic Beads is widely used as one Blasting Media?

Ceramic beads contains 62-66% ZrO2,its fine microstructure ensures

it has the characteristics of high hardness,

strong mechanical resistance,good elasticity,it is more durable,not

easy to be broken in the blasting process;

Ceramic beads has higher density than the one of glass beads,and

lower density than the one of steel shot,it will

make up the upper and lower limit gap between glass beads and steel

shot,therefore ceramic beads is able to

replace them in many applications;

Ceramic beads has lower breakdown rate,then little dust

generated,it will provide a clean and good blasting sight

for the operator;People do not need to refuel the new beads

frequently,the beads will be kept the same shape and

quality in the blasting machine,then it will achieve one more

consistent blasting effect from the first part to the last;

5. Main Applications of Ceramic Bead Blasting

Surface cleaning to remove the rust,oil stain and impurities of

various molds such as glass bottles,tires and dies,

automotive molds,plastics molds,forged and casted metal etc.

Surface cleaning for the inner and outer walls of various metal

pipes such as copper pipes,steel pipes.

6. Why Choose Zirnano Ceramic Beads?

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning

under high temperature,which provides

higher clearliness and ensures it to be work normally in humid

weather;

More concentrated particle size distribution

B400(0.030-0.063μm) is more concentrated than the other

one(0-0.063μm) from other company,which will achieve

better blasting effect.

Multiple Authentication

Certificated by ISO9001 ISO14001,SGS,ROHS

Stable supplier of Foxconn,Ujiden,Samsung Electronics,Tongda Group

etc

Products in good quality & stable performance,competitive

price,flexible payment terms.