Ceramic Abrasive Blasting Media B80 size 0.180-0.250mm for alu

profiles blasting

1. What is Ceramic Abrasive Blasting Media

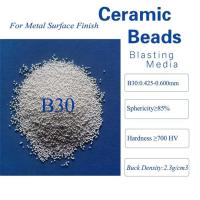

Ceramic abrasive blasting media is ceramic beads, it is a kind of

abrasive blasting media, also called zirconia sand.

Ceramic abrasive blasting media is a spherical bead produced by

electro-fusion process with dense crystal structure. Its structure

is Zirconium crystals in a glassy silicon dioxide cover, which

leads the it of high density and high shock resistance, not easy to

reform and break, so ensures its surface finishing consistency

Ceramic abrasive blasting media is usually used for sandblasting

before anodizing of industrial aluminum profiles.

2. Specification of Ceramic Abrasive Blasting Media

| Product | Process | Specific Density | Bulk Density | Vickers Hardness |

| Ceramic beads | Electro-fusing | 3.85 (g/cm³) | 2.3 (g/cm³) | 700 HV |

| Chemical Components | ZrO2 62-68% | SiO2 25-30% | Al2O3 7-13% | Other 1% Max. |

Size Available

(mm) | Blasting-clean/Surface finish | Shot peening |

| B20: 0.600-0.850mm | Z150: 0.150-0.210mm, |

| B30: 0.425-0.600mm | Z210: 0.210-0.300mm |

| B40: 0.250-0.425mm | Z300: 0.300-0.425mm, |

| B60: 0.125-0.250mm | Z425: 0.425-0.600mm, |

| B80: 0.180-0.250mm | Z600: 0.600-0.850mm |

| B100: 0.128-0.18mm | Z850:0.850-1.180mm |

| B120: 0.063-0.125mm | Other sizes can be customized against customers’ requirement. |

| B170: 0.045-0.090mm |

| B205 : 0.000-0.063mm |

| B400: 0.000-0.063mm |

3. Features of Ceramic Abrasive Blasting Media

- 1. High hardness and small deformation ensures surface consistency.

- 2. High density and high strength, leads high blasting efficiency

- 3. Applicable for various materials like stainless steel, aluminum

alloys and titanium alloys, etc.

- 4. Low breaking rate and no dust

4. How does Ceramic Abrasive Blasting Media working

5. Application of Ceramic Abrasive Blasting Media

The industrial aluminum profiles we produce often use a sandblasted

oxide finish by ceramic abrasive blasting media.

Sandblasting oxidation is an additional sandblasting step before

the anodizing and coloring of the aluminum profile.

Sandblasting is to slowly pass the industrial aluminum profile

through the sandblasting machine, and the inside of the

sandblasting machine will spray very fine ceramic abrasive blasting

media to make even small pits on the surface of the aluminum

profile, which looks like a matte effect, which is better than the

bright appearance. mild.

At the same time, sandblasting can also remove surface defects such

as burrs, scratches, corrosion spots, blisters, pores, etc. on the

surface of the workpiece, and further remove the subtle unevenness

on the surface of the workpiece, making it have a higher satin

luster.

Ceramic abrasive blasting media has different particle sizes, the

larger the number, the finer the ceramic beads, and the smaller the

surface roughness of the sandblasting.

After ceramic abrasive blasting media can:

Provide good surface conditions and improve the quality of surface

finishing;

Obtain a clean surface;

Reduce the impact of welding;

Produce decorative effects;

Improve product quality;

Besides pre-treatment of blasting before anodizing of industrial

aluminum profiles, it has other applications as below: