2.Sandblasting Ceramic Beads B170 size 0.045-0.090mm for metal

surface treatment

DESCRIPTION OF CERAMIC BEADS

Sandblastinge Ceramic bead is also called zirconia sand. It is

zirconia-based blasting media, obtained in melting method and then

blowing into muciro beads. The sandblasting ceramic beads are no

dust, durable and efficient, offering consistent surface finishing,

are new eco-friendly blasting material, widely used for blast matte

finish, blast surface cleaning and surface preparation before

coating or anodizing.

Mainly used in sandblasting machine, including Manual & Automatic

sandblasting machine, Open type sandblasting machine and

Sandblasting machine room, and shot peening equipment, etc.

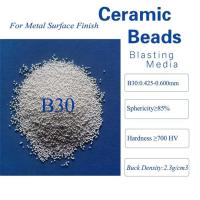

SPECIFICATION OF CERAMIC BEADS

Manufacturing process: Melting method

| ZrO2 | SiO2 | Al2O3 | Other |

| 60-66%, | 25-30% max. | 7-13% max. | 5-8% |

| Color | Bulk Density | True Specific Density | Vickers Hardness |

| White | 2.3g/cm3 | 3.85g/cm3 | 700 HV |

| Grit size | B20 | B30 | B40 | B60 | B80 | B100 | B120 |

| Microns μm | 600-850 | 425-600 | 250-425 | 125-250 | 180-250 | 125-180 | 63-125 |

| Grit size | B125 | B170 | B205 | B400 | B505 | Special sizes

can be customized |

| Microns μm | 0-125 | 45-90 | 0-63 | 30-63 | 0-63 |

| Grit size | Z850 | Z600 | Z425 | Z300 | Z210 | Z150 | Z100 |

| Microns | 850-1180 | 600-850 | 425-600 | 300-425 | 210-300 | 150-210 | 100-150 |

COMPARISION OF SANDBLASTING OF CERAMIC BEADS VS GLASS BEADS

We have some study on the comparison on cost of blasting and life

against ceramic beads and glass beads.

Ceramic Beads and Glass Beads dosage and solid waste comparison

| Workpiece | Blasting Media | Consumption Mothly | Dust | Dust disposal cost |

| Aluminium alloy | Glass beads 150# | 6 Tons | Much | High |

| Aluminium alloy | Ceramic beads B170 | 0.2Tons | Very Little | Low |

This customer used glass beads to treat aluminum alloy before, and

the monthly consumption of glass beads was about 6 tons. Because

the glass beads are fragile, a large amount of dust solid waste is

generated after use, and additional costs are required to deal with

the solid waste every month.

After replacing glass beads with ceramic beads, the monthly

consumption of ceramic beads is only 0.2 tons, which not only saves

material costs, but also reduces the cost of solid waste treatment

and improves work efficiency.

Ceramic beads is not easy to be broken during sandblasting, and it

is almost no dust pollution , which also improves the working

environment of workers and keeps them away from silicosis hazards.

Remarks:

Under the conditions of different workpieces, different blasting

pressure conditions and blasting requirements, the reduction in the

amount of ceramic beads after replacing glass beads is different.

The above is for reference only.

APPLICATION OF CERAMIC BEADS

1. SANDBLASTING FOR ALUMINIUM PROFILES

In the sandblasting process using ceramic beads as blasting media,

the surface is formed with uniform pits, which are so small that we

can hardly see them with the naked eye. We can only see that the

originally bright aluminum products have become matte.

Sandblasting and anodizing process application:

Widely used in aviation, electrical, electronic digital industry,

machinery manufacturing, automobile, construction, light industry

and other industries.

Sandblasting process classification:

According to different workpiece materials, anodizing treatment is

divided into ferrous metals (steel) and non-ferrous metals

(aluminum, copper, magnesium and their alloys);

The advantages by ceramic beads sandblasting are:

1. Remove the oxide film on the surface of aluminum profile

products, whether it is a naturally formed oxide film or an

anodized film, it can be completely removed after sandblasting.

This is why the sandblasting process precedes the anodizing

sequence.

2. Prepare for other surface treatment procedures. When the

aluminum profile after sandblasting is electroplated, the bonding

force of the electroplating layer is stronger. The sandblasted

aluminum profile can also be sprayed to enhance the coating

adhesion.

2. OTHER APPLICTIONS

Includes metal surface treatment, metal rust removal, hardware rust

removal, stainless steel material sandblasting, copper material

sandblasting, hardware paint removal, hardware scar removal,

aluminum alloy deburring, Zinc alloy blasting finish. etc.