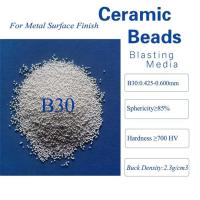

Mircosphere Ceramic Bead Blasting Media B60 B80 B100 B120 for

Titanium Alloy,Magnesium Alloy

1. Product Description

Ceramic beads is also called as ceramic blasting media,It also has

the round shape as the on of glass

beads,while it is one clean and high efficient blasting media,which

will provide more consistent blasting

effect and lower dust compared with glass beads.

Here simply list the comparation between ceramic beads and glass

beads as below:

| Item | Ceramic Blasting Beads | Glass Beads |

| Chemical Index | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% |

SiO2:>65%,Na2O<14.0%

CaO>8.0%,MgO>2.5%

Al2O3 0.5-2.0% Fe2O3:0.15

|

|

|

| Vickers Hardness | ≥700 HV | ≥560HV |

| True Specific Gravity | ≥3.85 g/cm3 | ≥2.5g/cm3 |

| Usage | Blasting Media | Blasting Media |

| Ferrous Contamination | No Ferrous | No Ferrous |

| Dust Pollution | Little | Large |

| Recyclable Times | 70-90 | 9-12 |

| Breakdown Rate | 1.20% | 10% |

| Equipment Wear Rate | Low | Low |

| Blasting Effect | High finish

No discoloration | High finish

White discoloration |

| Particle Size Comparation |

| Ceramic Beads | Glass Beads |

| B20: 0.600-0.850mm | 30#:0.425-0.850mm |

| B30:0.425-0.600mm | 40#: 0.425-0.600mm |

| B40:0.250-0.425mm | 60#:0.300-0.425mm |

| B60:0.150-0.300mm | 80#:0.150-0.300mm |

| B80:0.125-0.212mm | 100#:0.106-0.212mm |

| B100:0.106-0.180mm | 120#:0.106-0.150mm |

| B120:0.063-0.125mm | 150#:0.075-0.150mm |

| B150:0.000-0.125mm | 180#:0.075-0.106mm |

| B170:0.045-0.090mm | 220#:0.053-0.106mm |

| B205: 0.000-0.063mm | 280#:0.045-0.075mm |

| B400: 0.030-0.063mm | 320#:0.001-0.050mm |

| B505: 0.010-0.030mm | / |

| Special Specification can be customized |

Seen from the above charts,ceramic beads has different particle

size and chemical composition of glass

beads,it is more durable in blasting process,also a high efficient

blasting media.

It is able to replace glass beads,where one clean blasting

condition is required.

2. Main Applications of Ceramic Beads

Ceramic beads can replace glass beads in metal surface finish such

as aluminum parts, aluminium alloy,

titanium alloy,magnesium alloy, stainless steel parts...

3. Applicable Equipment

Manual Sandblasting machine;

Automatic Blasting Machine;

Open Blasting Machine;

Sandblasting room;

4. Why ceramic beads is one clean and high efficient blasting

media?

Ceramic beads has dense crystal structure and higher hardness,it is

not easy to be broken in the blasting

process,the un-broken beads will keep its original shape and

property,then people don’t need to refuel it

frequently and improve the blasting efficiency.

Meanwhile,it generates little dust,which will provide one clean

working condition,also keep the worker

escaping from the hidden danger of silicosis.

In addition,it also greatly reduce the treatment cost of solid

waste.

Therefore it is one clean and high efficient blasting media.

5. How to store ceramic beads?

Packing ceramic beads in a dry sealed barrel;

Store it in a dry and ventilated indoor warehouse;

Use up ASAP once unsealed.