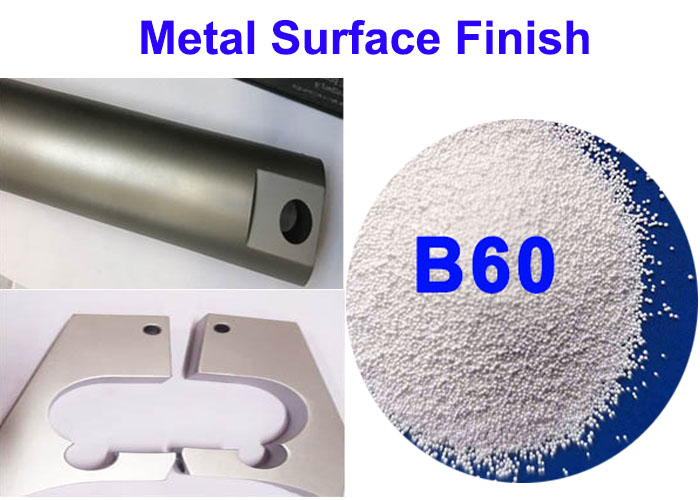

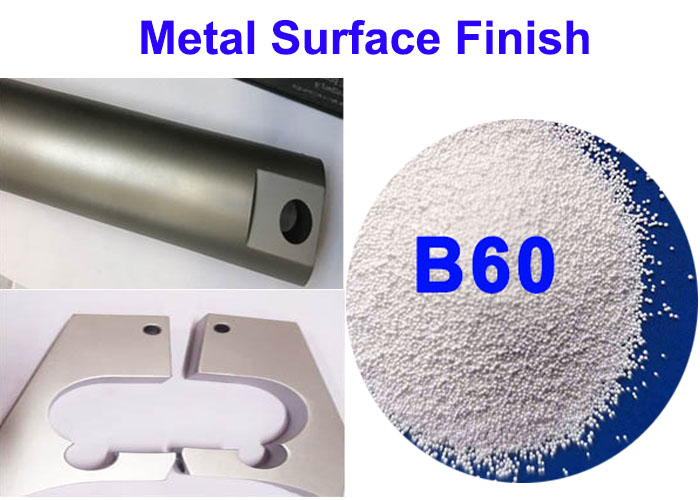

Iron-free Ceramic Beads Blasting Media B60 B120 for Stainless Steel

Parts Surface Finish

1. Product Description of Ceramic Beads Blasting Media

Ceramic Beads is one solid round blasting media,it selects the high

quality imported zircon sand as

main material, fused in high temperature,then finally made into

different size from B20 to B505 by

special technology.

Ceramic beads has wide particle size,which is able to meet almost

blasting equipments.

The more popular size is

B40(0.425-0.600mm),B60(0.150-0.300mm),B120(0.063-0.125mm),B170

(0.045-0.090mm),B205(0-0.063mm).

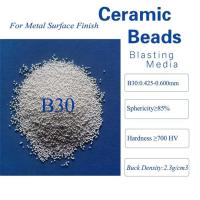

2. Main Technical Data of Ceramic Beads Blasting Media

| Commodity Name | Chemical Index | Physical Index |

Ceramic Beads | ZrO2 60-66%

SiO2 25-30%

Al2O3 7-13% | Vickers Hardness ≥700 HV

Bulk Density≥2.3g/cm3

True Gravity: 3.85g/cm3

Process: Melting |

|

|

| Particle Size for Ceramic Blasting Media |

| B20: 0.600-0.850mm | B120: 0.063-0.125mm |

| B30: 0.425-0.600mm | B150:0-125μm |

| B40:0.250-0.425mm | B170: 0.045-0.090mm |

| B60:0.150-0.300mm | B205: 0-0.063mm |

| B80:0.125-0.212mm | B400: 0.030-0.063mm |

| B100:0.106-0.180mm | B505: 0.010-0.030mm |

| Particle Size for Ceramic Shot Peening |

| Z100: 0.100-0.150mm | Z150: 0.150-0.210mm |

| Z210:0. 210-0.300mm | Z300: 0.300-0.425mm |

| Z425:0.425-0.600mm | Z600: 0.600-0.850mm |

| Z850: 0.850-1.180mm | ./ |

| Remark: Special specification can be customized. |

3. Main Applications of Ceramic Beads Blasting Media

Surface finish for metal parts to achieve one satin blasting

effect;

Surface preparation for electroplating or anodizing to achieve a

certain surface roughness;

Surface finish for medical instruments to remove the microburrs and

make small round conners at the

junctions of two surface to finally achieve the most smoothness

texture;

Surface reinforcement for automotive parts to eliminate the surface

stress and improve the surface strength.

4. Applicable Equipments of Ceramic Beads

Manual sandblasting machine

Annual Sandblasting Machine

Sandblasting room

5. Why Ceramic Beads is widely used in blasting industries?

Ceramic beads has round smooth surface,high hardness and

strength,which can be rebounded in multi-angles

in the blasting process,it will bring little damage to the blasting

equipments.

Ceramic beads has dense crystal structure and lower break-down

rate,the non-broken beads will maintain its

original shape and property. Then the beads in blasting machine

will be almost the same quantity,which will

save the refuel time and finally achieve more consistent blasting

effect.

Compared with glass beads,the service life of ceramic beads can be

prolonged to be 25-30 times,which will

save the blasting cost.

Little dust generated in blasting process,which will provide one

clean and bright working condition,no hidden

danger of silicosis to the worker. Meanwhile,it also greatly save

the treatment cost of solid waste.

Therefore,ceramic beads is one clean and high efficient blasting

media, which is gradually used to replace

glass beads and widely used in blasting industries.