62-66% ZrO2 Ceramic Bead Blasting Media B60 0.063-0.125mm for Stainless Steel

Surface

1. Product Description of Ceramic Bead

Ceramic bead is one clean and high efficient blasting media,it

selects the premium zircon sand as main raw

material,then fused in an electric furnace under high

temperature,finally made into different specification

accordingly.

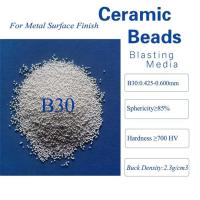

2. Main Technical Data of Ceramic Bead

| Main Index of Ceramic Bead Blasting |

| ZrO2 | SiO2 | Al2O3 |

| 60-66% | 25-30% | 7-13% |

| Vicker Hardness | True Specific Gravity | Bulk Density |

| ≥700 HV | ≥3.85 g/cm3 | 2.3g/cm3 |

| Particle Size |

| B20: 0.600-0.850mm | B100: 0.125-0.180mm |

| B30: 0.425-0.600mm | B120: 0.063-0.125mm |

| B40: 0.250-0.425mm | B170: 0.045-0.090mm |

| B60: 0.125-0.250mm | B205: 0.000-0.063mm |

| B80: 0.180-0.250mm | B400: 0.030-0.063mm |

| Remark: Special specification can be customized |

3. Why ceramic bead can replace glass beads in many applications?

Longer service life and more consistent blasting effect;

Ceramic beads contains 62-66% ZrO2,it has higher hardness and more

wear-resistant rate compared with

glass beads, ceramic beads is not easy to be breakdown in the whole

blasting process,the beads in the

blasting machine will almost maintain the original shape and

performance,which will achieve the consistent

blasting effect.

Better Blasting Sight, Lower Beads consumption

Since ceramic beads has lower breakdown rate,it will generate

little dust in the blasting process,finally providing

better blasting sight;Even the breakdown beads will keep the

original shape and performance,then people do

not need to refuel the new beads frequently,it also reduce the bead

consumption greatly.

4. Main Application of Ceramic Beads

Ceramic Bead B20,B30 for shot peening in metal surface;

Ceramic Bead B40, B60 for glass mold cleaning,stainless-steel

surface treatment as well as Die-cast aluminum;

Ceramic Bead B120 for surface finish in artifical joint and golf

club;

Ceramic Bead B170,B205 for surface finish in metal surface &

built-in parts of 3C Products

5. The consumption contrast between Ceramic Beads & Glass Beads

| For the same Treated Parts | Blasting Media | Month Consumption | Solid Waste Q'ty | Total cost |

| Die-cast aluminum parts | Glass Beads 60# | 7.0mts | large quantity | High |

| Ceramic Beads B60 | 0.1mt | Small quantity | Low |

The above is one true testing result from our client,obviously

ceramic beads has lower bead consumption,

it not only reduces the blasting cost greatly,but also provides one

clean working condition for the operators.

6. Why choose us?

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning

under high temperature,which provides

higher clearliness and ensures it to be work normally in humid

weather;

More concentrated particle size distribution

B170(0.045-0.090μm),B400(0.030-0.063μm) is more concentrated than

the other one(0-0.063μm) from other

company,which will achieve better blasting effect.

More competitive price

Our plant is located in mountain area,which provides lower cost in

environmental protection and workers’ salary,

then the product price is more competitive than the one of other

plants.

More flexible corporation model

No matter you are the distributor or final users,we will provide

the more flexible payment term and corporation model.