Ceramic Bead Blasting B120,B100,B60 surface finishing for Golf

Club/Medical Instrument/Titanium alloy/ Magnesium alloy

1. Product Description of Ceramic Bead Blasting

Ceramic bead is one white and round ball,which is made from

zirconium sand in one electric

furnace under high temperature over 2000℃,then made into different

micro bead through the

special technology.

Ceramic Bead is one clean & high efficiency blasting media,compared

with the glass beads,it is not easy to breakdown in the

blasting process, which generate little dust, the operator is able

to work in one good blasting sight and has no hidden danger of

silicisos.

2. Main Technical Data of Ceramic Bead Blasting

| ZrO2 | SiO2 | Al2O3 |

| 60-66% | 25-30% | 7-13% |

| Vicker Hardness | True Specific Gravity | Bulk Density |

| ≥700 HV | ≥3.85 g/cm3 | 2.3g/cm3 |

3. Main Features of Ceramic Bead Blasting

Ceramic bead is one popular blast media with a low breakdown

rate,which provides consistent surfce

finish and low consumption rate.

Ceramic bead contains 62-66% ZrO2,which provide high hardness and

good impact force

Ceramic bead is one clean blasting media,it will generate little

dust and provide a good blasting sight

for operator;

Ceramic Beads has wide particle size distribution,it is suitable

for all kinds of blasting equipment.

Its round shape and white color ensures it no damage or

contamination to the blasting equipment

and treatment.

4. Main Application of Surface Finish

Surface finishing for golf club etc;

Surface finishing to remove the micro burrs in delicate parts such

as in the medical instrument and

make small rounded connersat the junction of two surfaces,enhance

the smoothness and texture.

5. Applicable Equipment

Manual Sandblasting machine;

Automatic Blasting Machine;

Open Blasting Machine;

Sandblasting Room

6. Why choose us

Our ceramic beads has the outstanding advantages:

Higher clearliness

Our ceramic bead are screened more than six times and blow-cleaning

under high temperature,

which provides higher clearliness and ensures it to be work

normally in humid weather;

More concentrated particle size distribution

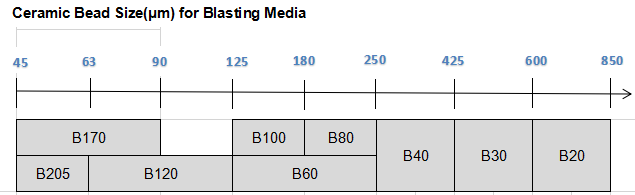

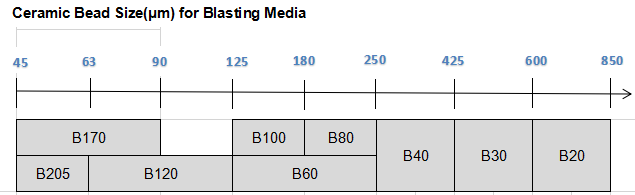

B170(0.045-0.090μm),B205(0.045-0.063μm) is more concentrated than

the other one(0-0.063μm) from

other company,which will achieve better blasting effect.

High price/performance Ratio

Our factory is located in the mountain area,where has the lower

production cost and environmental cost,

So price is more competitive.