Low breakage rate Ceramic Foundry Sand

20/40#,30/50#,40/70#,50/100#,70/140# For Sodium

Silicate Sand

1. Product Description of Ceramic Sand

Ceramsite is also called as Ceramic foundry sand.It selects the

high quality bauxite as main raw material,

then made into different size through the process of calcination,

electric melting, granulation, and sieving.

Ceramic sand has high refractoriness over 1790℃, it can help to reduce the sand adhering to the casting

parts,especially when used for steel castings & stainless steel

parts with higher temperature.So it is an

advanced substitute for quartz sand in casting industries.

2. Main Technical Data of Ceramic Sand

| Commodity | Main Chemical Index | Main Physical Index |

| Ceramic Sand | Al2O3 ≥70%

Fe2O3 ≤3%

SiO2≤18%

TiO2≤3.5%

K2O3+Na2O <1%

CaO+MgO<1%

L.O.I <0.3% | Shape: Round

Color:Gray Brown

Refractoriness:≥1790 ℃

Bulk Density:1.9-2.1g/cm3

True Gravity:3.30g/cm3

Coefficient of Expansion:0.13%

(Heat 10Minutes under 2000℃)

PH:7-8

Thermal Conductivity:0.698W/m*K

(Heated Surface 800℃)

Angle coefficient:≤1.1

(Very similar to spherical)

Water Content≤0.1%

Mud Content≤0.1%

Average Coefficient of Linear Expansion≤6*10-6℃-1 |

| Grit Size | 14#,20#,30#,40#,50#,70#,100#,140#,200#,270# |

| Section Sand | 14/20,20/30,20/40,20/50,30/50,40/50,40/70,50/100 |

| 50/140,70/140,70/200,100/200,140/270,200/270 |

| Remark | Special specification can be customized |

3. Main Features of Ceramic Sand

Solid Sphere: Ceramsite has solid spherical shape with smooth

surface,it will provide good flowability and

filling ability.

Low thermal expansion rate: it will guarantee the casting size,

provide less crack and defect and improve

the output.

Low breakage rate: ceramsite has higher density and lower breakage

rate at the reclaimation,which provide

one better reclaimation rate,then reduce the production cost.

High refractoriness: ceramsite contains Min. 70% Al2O3,which

provide good refractory performance,then

suitable for all kinds of metal and alloy castings.

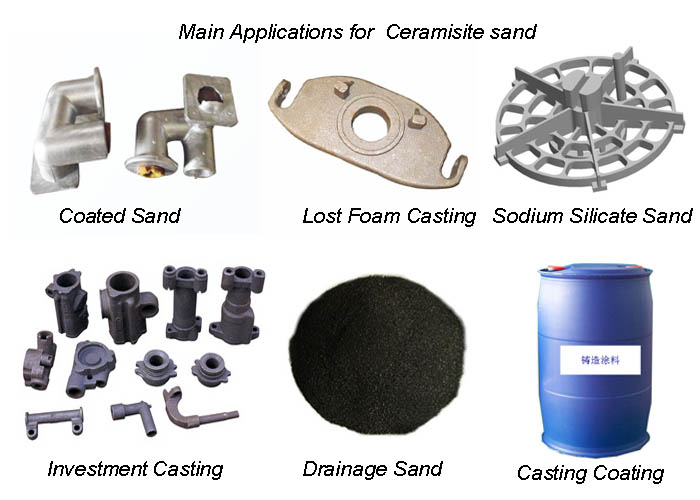

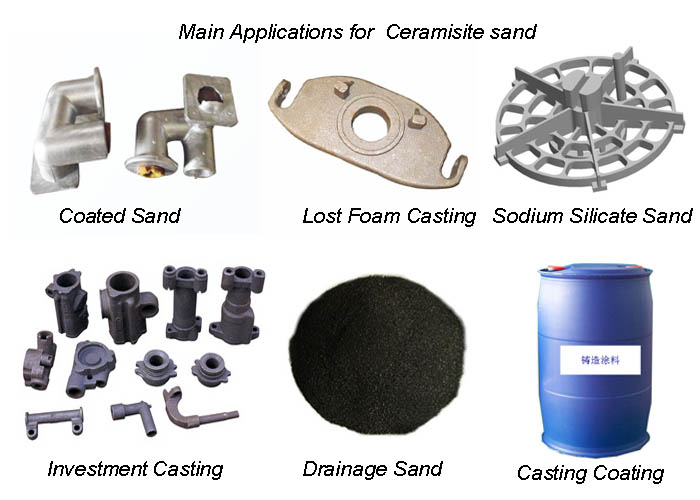

4. Main Applications & corresponding specification:

Lost Foam casting: Ceramsite 14#,20#,30#,14/20#,20/30#,20/40#

Investment casting: Ceramsite 100/200#

Sodium silicate sand:20/40#,30/50#,40/70#,50/100#,70/140#

Casting coating: 200#,270#,200/270#

Drainage sand: 20/30#,20/40#

Alloy surface treatment:40#,140#

Resin sand:40/70#,50/100#,50/140#,70/140#,100/200#

5. How to store the ceramic sand?

Use strong moisture-proof package;

Keep it in clean, dry and ventilated place;

Keep away from dust.

6. Why Ceramic Sand can replace the chromium sand as drainage sand?

Ceramic sand has lower bulk density and price compared with

chromium sand,it will reduce the sand

consumption and final production cost.

Ceramic sand also has higher cast ratio,it will effectively reduce

the strength of sintering layer,it is helpfu

to drain;

Its lower thermal expansion rate can reduce the expansion rate and

improve the yield rate.